Dashboard indicators explained: what electrical alerts mean

Modern vehicle dashboards show electrical alerts that can indicate anything from a low battery to a wiring fault. This article clarifies common symbols and the steps to inspect and diagnose electrical warnings so you can respond safely and maintain reliability.

Dashboards group a lot of electrical information into simple lights and symbols. When an electrical alert illuminates, it can signal a minor issue like a loose connector or a more serious problem involving the charging system, starter, or wiring. Recognizing what each indicator generally means, knowing basic inspection steps, and understanding when to use a multimeter or seek diagnostics can help you protect safety and avoid costly repairs.

Battery and charging alerts

A battery or charging light usually appears when the vehicle’s charging system is not keeping battery voltage at the proper level. That could mean a weak battery, a failing alternator diode, a loose belt, or corroded connectors at the battery terminals. Start by checking visible wiring and connectors for corrosion or looseness, then inspect the battery voltage with a multimeter at rest (typically around 12.4–12.7 volts for a healthy charge). If voltage drops significantly when the engine is running, the alternator may not be charging properly.

Alternator warning: causes and checks

Alternator-related alerts often point to low charging voltage or irregular output. Symptoms include dimming lights, electrical accessories cutting out, or a battery warning light. With the engine running, measure voltage at the battery: a healthy charging system usually reads about 13.5–14.8 volts. If readings are below or fluctuate widely, the alternator or its internal regulator could be at fault.

If the alternator checks out electrically but charging remains inconsistent, inspect the serpentine belt and tensioner for wear or slippage and confirm connectors and ground points are clean. Loose or damaged wiring between the alternator and battery can mimic a failed alternator, so trace cables and clean terminals before replacing major components.

Starter, connectors and wiring issues?

A dashboard alert alone may not always name the starter, but starter problems can cause related warnings when cranking fails or voltage drops during start. Corroded or loose connectors at the battery, starter, or ground points increase resistance and reduce current flow, triggering electrical alerts. Regular visual inspection of wiring harnesses for rubbing, melting, or rodent damage helps catch problems early.

When dealing with the starter circuit, measure voltage at the battery while cranking. If voltage falls below roughly 9.6 volts during start, the battery may be weak or connections inefficient. Tighten connectors, clean contact surfaces, and replace damaged cables or terminals rather than relying solely on replacing major components.

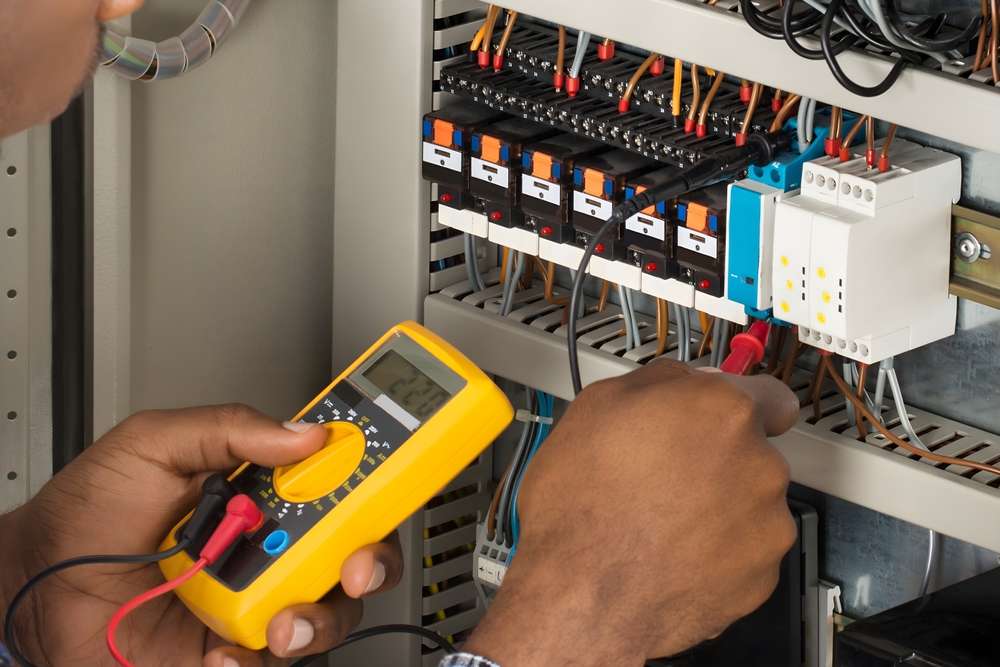

Voltage readings and multimeter diagnostics

A digital multimeter is a key diagnostic tool for electrical alerts. Use it to measure battery voltage (engine off and running), alternator output, and voltage drop across connections. For voltage drop tests, place the meter across suspect connectors while a circuit is under load; a significant drop indicates excessive resistance that warrants cleaning or replacement of the connector.

Simple diagnostics with a multimeter can distinguish between a weak battery, bad alternator, or wiring fault: stable charging voltage near 14 volts with a healthy battery implies wiring or accessory issues; low or fluctuating charging voltage suggests alternator or regulator problems. Keep manufacturer specifications handy when interpreting values.

Inspection and maintenance to prevent alerts

Routine inspection and maintenance reduce the chance of sudden electrical alerts. Check battery terminals and connectors for corrosion, ensure battery hold-downs keep terminals from vibrating loose, and examine fuses and fusible links for continuity. Clean grounds and connector pins, tighten loose connections, and replace brittle or damaged wiring before it fails.

Scheduled maintenance should also include belt inspection and replacement when showing wear, because a slipping belt can stop the alternator from charging effectively. For safety, disconnect the negative battery terminal before performing major electrical work and follow safe lifting and support practices when accessing components.

When to seek professional diagnostics and local services

If basic inspections and multimeter checks don’t identify a clear cause, professional diagnostics can use load testers, oscilloscope traces, or manufacturer scan tools to read system voltages, regulator signals, and error codes. Local services can perform comprehensive electrical diagnostics, identify intermittent faults, and handle repairs requiring specialist tools or replacement parts.

Document the symptoms you observed (which lights came on, any unusual noises, and voltage readings) to help technicians diagnose faster. Avoid driving long distances with an active charging-system warning, as an unmanaged electrical failure can leave you stranded or cause secondary damage to electronics.

Conclusion Electrical dashboard alerts condense complex systems into simple warnings; interpreting them requires a mix of visual inspection, basic multimeter tests, and knowledge of charging and starter behavior. Regular maintenance of battery terminals, connectors, belts, and wiring reduces the likelihood of warnings, while methodical diagnostics help distinguish battery, alternator, or wiring faults so repairs can be targeted and safe.